How many near-miss incidents happened in your warehouse last week that you don’t even know about? If you’re managing a busy facility with forklifts and pedestrians sharing the same space, the answer might surprise you: and it should definitely concern you.

The sobering reality is that nearly 80% of forklift accidents involve pedestrians, with over 90,000 injuries occurring annually across Australian workplaces. Even more alarming? Pedestrians account for 36% of all forklift-related fatalities. These aren’t just statistics: they represent real people, real families, and real businesses facing devastating consequences that could have been prevented.

But here’s what’s changing everything in 2026: AI-powered pedestrian detection systems are fundamentally transforming how warehouse managers approach safety. We’re not talking about incremental improvements to existing methods: this is a complete paradigm shift that’s making traditional safety approaches look dangerously outdated.

Why Traditional Safety Measures Are Failing Your Team

Let’s be honest about what’s not working. You’ve probably invested in high-vis vests, safety training programs, mirrors at blind corners, and maybe even proximity sensors. Yet accidents still happen, insurance claims keep rising, and you’re constantly worried about that one incident that could shut down operations.

The problem isn’t your safety commitment: it’s that traditional methods rely entirely on human awareness and compliance. Forklift operators get distracted, pedestrians take shortcuts, and in those split seconds when attention lapses, disasters occur. Your current safety measures are essentially hoping that every person, every time, makes the right decision under pressure.

What Makes 2026 Different? AI That Never Blinks

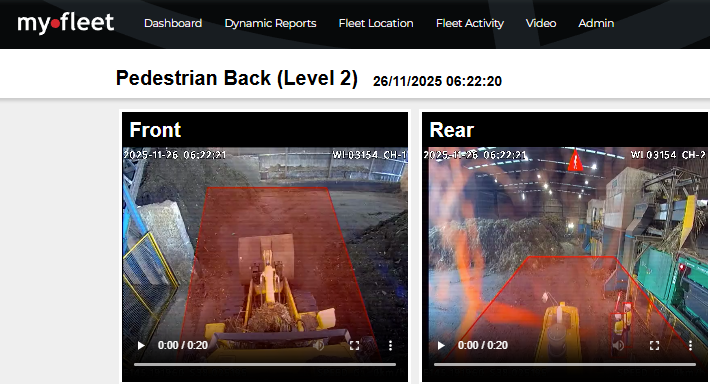

The game-changer arriving in warehouses across Australia is AI-powered pedestrian detection that operates completely independently of human awareness or compliance. Unlike systems that require workers to wear tags or devices, these camera-based solutions detect any pedestrian within 1-10 metres through 170 degree fields of view.

Here’s where it gets impressive: when a pedestrian enters a danger zone, the system doesn’t just sound an alarm: it can automatically reduce forklift speed or halt acceleration entirely. We’re talking about reaction times measured in milliseconds, not the precious seconds it takes for a human operator to notice, process, and respond to a hazard.

MyFleet’s extensive platform automatically uploads these incidents to the cloud for Management and Admins to view the footage and then review, classify and action these accordingly. MyFleet has a very easy to use filtering system to find and manage all videos you are looking for

Think about your busiest shift. How many times do operators get momentarily distracted checking their route, reaching for paperwork, or simply dealing with the cognitive load of managing a complex operation? AI detection systems eliminate those vulnerable moments entirely.

Are You Still Relying on Workers to Remember Safety Protocols?

One of the biggest advantages of modern pedestrian detection systems is their complete independence from worker participation. If you’ve ever tried implementing RFID or UWB proximity systems, you know the constant struggle of ensuring every person wears their tag, every shift, every day. Forget your tag? You’re invisible to the safety system.

AI vision systems flip this entire challenge on its head. They detect anyone within range: contractors, visitors, new employees, or that delivery driver who doesn’t know your safety protocols. The system doesn’t care if someone forgot their PPE or hasn’t completed your safety training yet. It protects them anyway.

This tag-free approach removes the biggest implementation barrier most warehouse managers face. You’re not fighting compliance issues, training new workers on device requirements, or dealing with lost or broken tags. The protection is automatic and universal.

How Data-Driven Safety Management Changes Everything

But prevention is just the beginning. The real transformation comes from the data these systems generate. Instead of waiting for accidents to tell you where problems exist, you’re getting real-time intelligence about near-miss incidents, high-risk zones, and patterns of unsafe behavior.

Imagine being able to identify that blind corner where three near-misses happened last week, or discovering that afternoon shift operators consistently have more pedestrian interactions in a specific area. This isn’t guesswork: it’s concrete data that lets you make targeted improvements to training, layouts, and procedures.

The compliance benefits alone are worth considering. These systems automatically document operator behavior, generate reports for safety audits, and provide evidence that demonstrates your proactive safety commitment. When OSHA comes calling or insurance companies want proof of your safety programs, you’ve got comprehensive data rather than paper checklists.

What About Complex Warehouse Layouts?

Modern facilities aren’t simple rectangles with clear sight lines. You’ve got narrow aisles, blind corners, multiple levels, and constantly changing configurations. Traditional safety measures struggle in these environments, but AI pedestrian detection systems are designed for exactly these challenges.

The latest systems support multi-camera configurations with independent alert zones, providing comprehensive 360-degree awareness. Each camera can be configured with different detection zones and response protocols based on the specific risks in that area. High-traffic intersections might trigger immediate speed reduction, while loading dock areas might have different alert parameters.

This scalability means the system grows with your operation. Adding new warehouse sections? Install additional cameras and integrate them seamlessly with your existing setup. The technology adapts to your facility rather than forcing you to adapt to the technology.

The Real Cost of Doing Nothing

Let’s talk numbers for a moment. Every prevented accident saves your operation an average of $180,000 when you factor in direct costs, productivity losses, regulatory penalties, and insurance impacts. But beyond the financial calculation, consider the operational disruption of a serious incident.

How long would your warehouse be shut down for investigation? What happens to your relationships with customers when you can’t fulfill orders? How do you rebuild team morale after a preventable injury? These ripple effects often cost far more than the immediate medical and legal expenses.

The Australian workplace safety landscape is becoming increasingly strict, with regulators taking a dim view of preventable incidents. Being able to demonstrate that you’ve implemented the most advanced available safety technology isn’t just good business: it’s becoming essential for regulatory compliance and insurance coverage.

Making the Transition in Your Facility

The beauty of modern pedestrian detection systems is their integration flexibility. Whether you’re running a standalone warehouse or part of a broader fleet operation, these systems can function independently or integrate with existing management platforms.

Many Australian facilities are starting with pilot programs in their highest-risk areas: loading docks, main thoroughfares, or areas with frequent pedestrian traffic. This allows you to demonstrate ROI and build confidence before expanding the system facility-wide.

Implementation doesn’t require massive infrastructure changes. Most systems work with standard IP camera networks and can leverage existing Wi-Fi or ethernet connections. The key is choosing a solution that can scale with your needs and integrate with your operational workflow.

Your Next Steps

The warehouse safety landscape is changing rapidly, and the facilities that adopt AI-powered pedestrian detection early will have significant advantages in safety performance, regulatory compliance, and operational efficiency. The question isn’t whether this technology will become standard: it’s whether you’ll be leading the change or scrambling to catch up.

If you’re ready to move beyond hoping your current safety measures are enough, it’s time to explore how advanced pedestrian detection can transform your warehouse safety program. The technology exists today, the ROI is proven, and your team’s safety is worth the investment.

Ready to see how modern fleet telematics and safety systems can protect your operation? Contact our team to discuss a pedestrian detection solution tailored to your facility’s specific needs. Because when it comes to workplace safety, good enough simply isn’t good enough anymore.