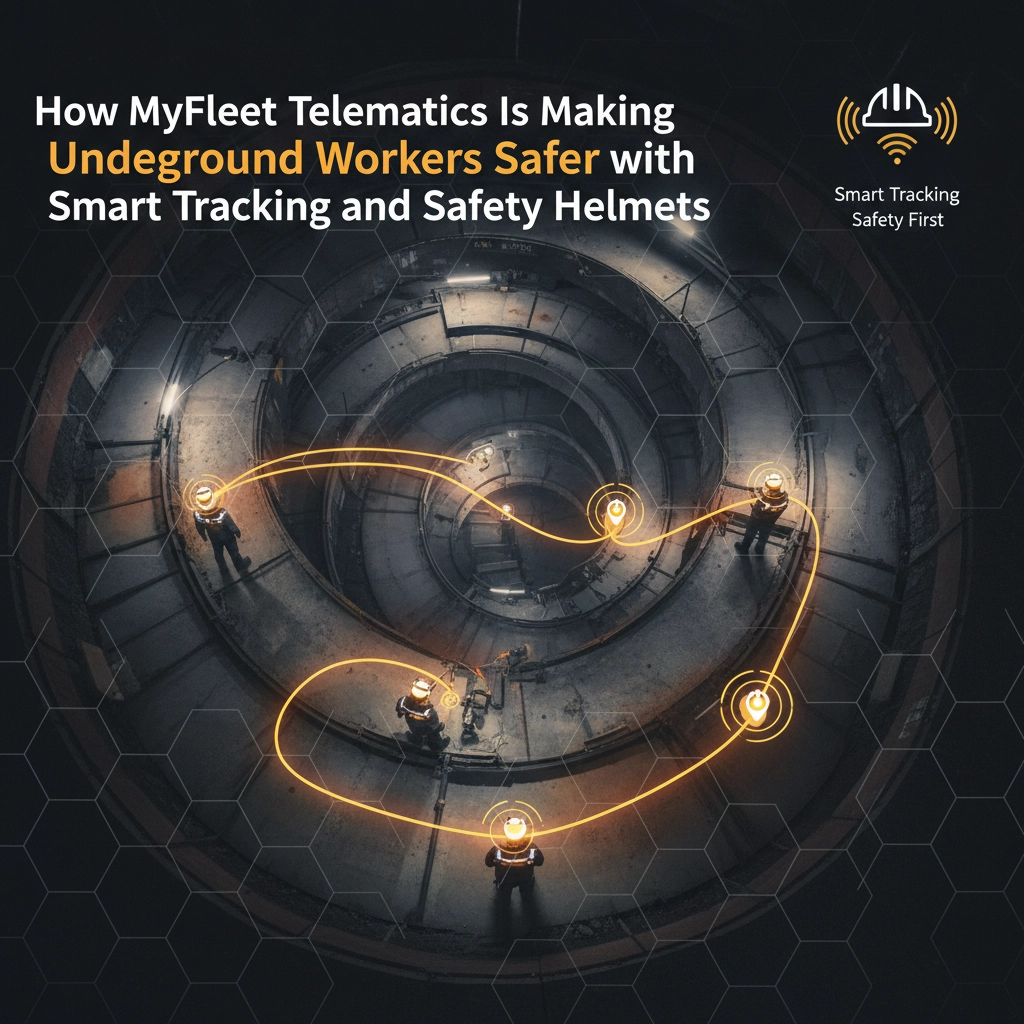

What happens when your underground workers face an emergency and there’s no way to call for help? If you’re managing teams in tunnels, mines, or other underground facilities, this question probably keeps you up at night. Traditional communication methods fail when you’re dealing with concrete barriers, signal dead zones, and the unpredictable nature of underground environments.

Here’s the reality: underground work environments present unique safety challenges that surface-level solutions simply can’t address. Workers can become isolated, disoriented, or trapped with no reliable way to communicate their location or distress. But what if your duress solutions could do more—delivering real-time worker tracking and instant duress alerts for faster emergency response in tunnels and mining environments? Adding Wifi routers along the tunnels to give your workers connectivity to make internet phone calls in case of emergency.

The Hidden Dangers Lurking Underground

Underground workers face risks that most people never consider. Beyond the obvious dangers of cave-ins or equipment failures, there’s the psychological stress of working in confined spaces, the difficulty of maintaining situational awareness in poorly lit environments, and the challenge of coordinating team movements when visibility is limited.

Traditional safety protocols rely heavily on buddy systems, scheduled check-ins, and radio communication. But what happens when radio signals can’t penetrate rock formations? What if a worker becomes separated from their team or loses consciousness?

When a worker activates the duress signal, the system immediately transmits their last known location along with their identity to surface monitoring teams. This isn’t just a basic “help” message – it’s a comprehensive alert that provides context for emergency responders.

Real-Time Location Tracking Underground

The location tracking component solves one of the biggest challenges in underground emergency response: knowing exactly where your people are when every tunnel looks the same and traditional GPS fails.

MyFleet’s telematics system creates detailed maps of underground work areas, tracking worker movements in real-time relative to known reference points. This means when an emergency occurs, response teams know not just that someone needs help, but precisely where to find them.

The system maintains this tracking capability even when workers move between different levels, through various tunnel systems, or into areas with limited connectivity. By creating a mesh network effect between multiple helmet units, the technology ensures that location data continues to transmit even when individual units temporarily lose direct surface contact.

How Instant Duress Alerts Save Lives

The duress button functionality goes beyond simple emergency calls. The system is designed to differentiate between intentional distress signals and accidental activations, reducing false alarms while ensuring genuine emergencies receive immediate attention.

When activated, the duress signal triggers multiple response protocols simultaneously. Surface teams receive instant notifications with location data, nearby workers get alerts about potential dangers in their area, and emergency services can be automatically contacted with precise location information.

This multi-layered approach significantly reduces emergency response times. Instead of waiting for someone to notice a worker hasn’t returned from their assigned area, help is already on the way within minutes of an incident occurring.

Beyond Emergency Response: Daily Safety Benefits

While emergency response capabilities grab attention, the daily safety benefits of smart helmet tracking provide ongoing value. Supervisors can monitor team locations throughout shifts, ensuring workers don’t accidentally enter dangerous areas or become isolated from their teams.

The system also tracks movement patterns, helping identify potential safety hazards before they cause problems. If workers consistently avoid certain areas or take longer routes, this data can reveal underlying issues with workplace design or safety protocols.

Work zone management becomes more precise when you can see real-time team positions. Supervisors can coordinate activities more effectively, prevent teams from interfering with each other’s work, and ensure evacuation procedures can be executed quickly if needed.

Practical Implementation for Site Managers

Rolling out smart helmet technology doesn’t require overhauling your entire safety program. The MyFleet system integrates with existing safety protocols, enhancing rather than replacing current procedures.

Worker training focuses on the duress button functionality and basic system awareness. Most teams adapt quickly because the technology doesn’t change their core work activities – it simply adds an invisible safety net that operates in the background.

The monitoring interface provides site managers with clear dashboards showing team locations, system status, and alert histories. This visibility enables better decision-making about work assignments, safety protocols, and emergency preparedness.

Measuring the Return on Safety Investment

Smart helmet tracking systems deliver measurable benefits beyond safety improvements. Reduced emergency response times translate to lower incident costs, decreased insurance premiums, and improved regulatory compliance ratings.

The location tracking data also provides valuable insights for operational efficiency. Understanding how teams move through work areas can reveal opportunities for workflow improvements, equipment positioning optimization, and more effective site layout planning.

Companies implementing comprehensive underground worker tracking typically see improved worker confidence and morale. When employees know help is always just a button press away, they approach their work with greater confidence and focus.

What This Means for Your Underground Operations

If you’re responsible for underground worker safety, the question isn’t whether you need better tracking and communication systems – it’s how quickly you can implement them. Every day without comprehensive safety coverage is a day when your teams face unnecessary risks.

MyFleet’s smart helmet and telematics solution addresses the specific challenges of underground work environments. The technology provides the real-time visibility and emergency response capabilities that traditional safety equipment simply cannot deliver.

The investment in advanced safety technology often pays for itself through reduced incidents, improved compliance, and enhanced operational efficiency. But the real value lies in knowing your teams have the best possible protection when they head underground each day.

Ready to learn how MyFleet’s smart tracking and duress systems can enhance safety for your underground workers? Contact our team to discuss your specific requirements and see how this technology can be adapted for your operations.